Product Description

## 2D-to 3D-Conversion and 3D-printing services include ##

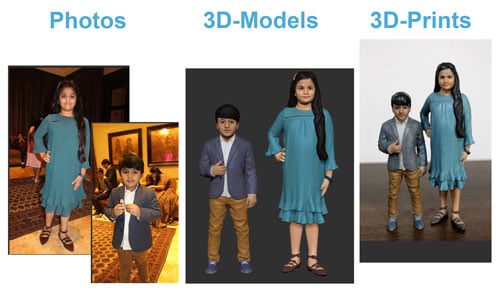

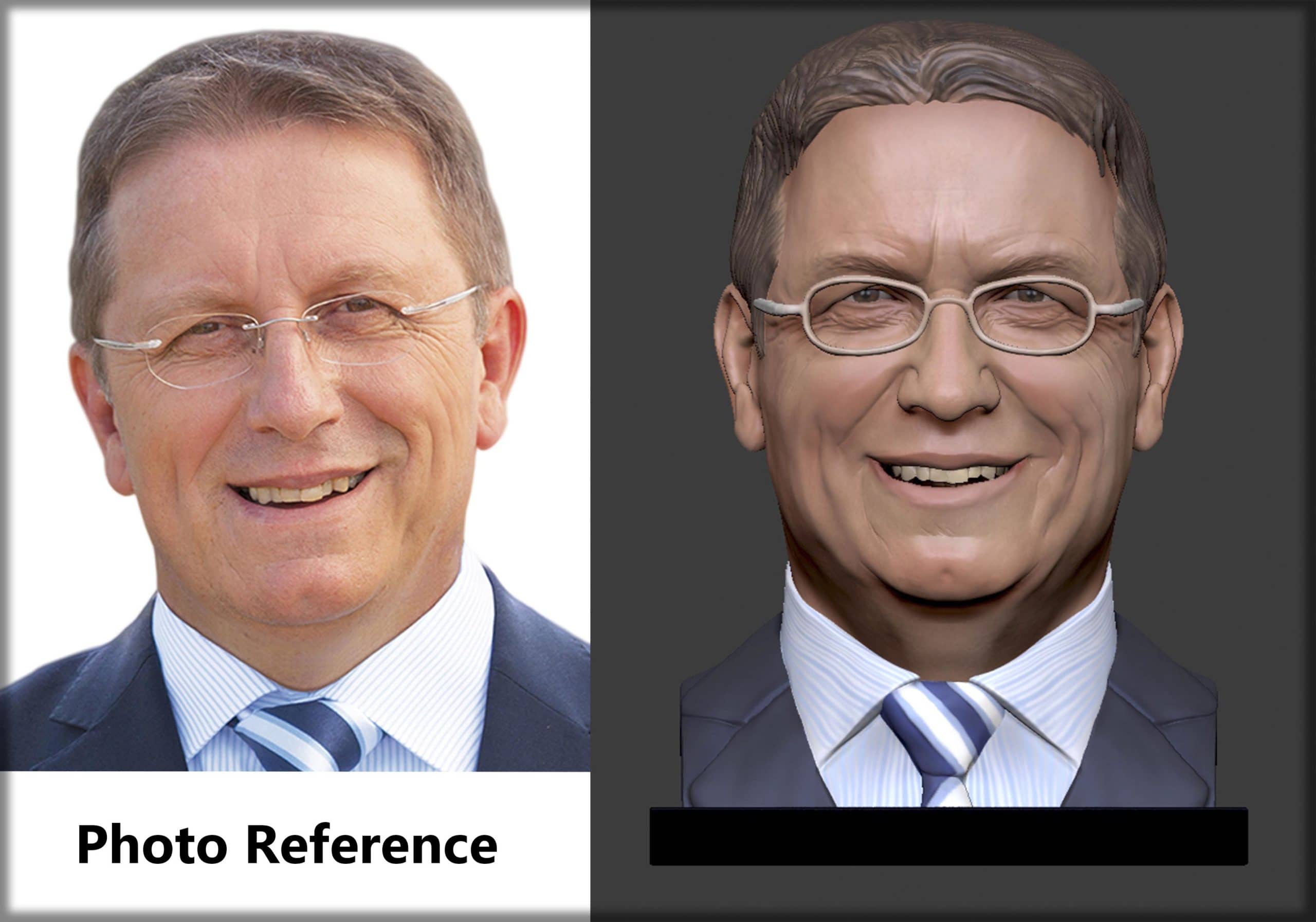

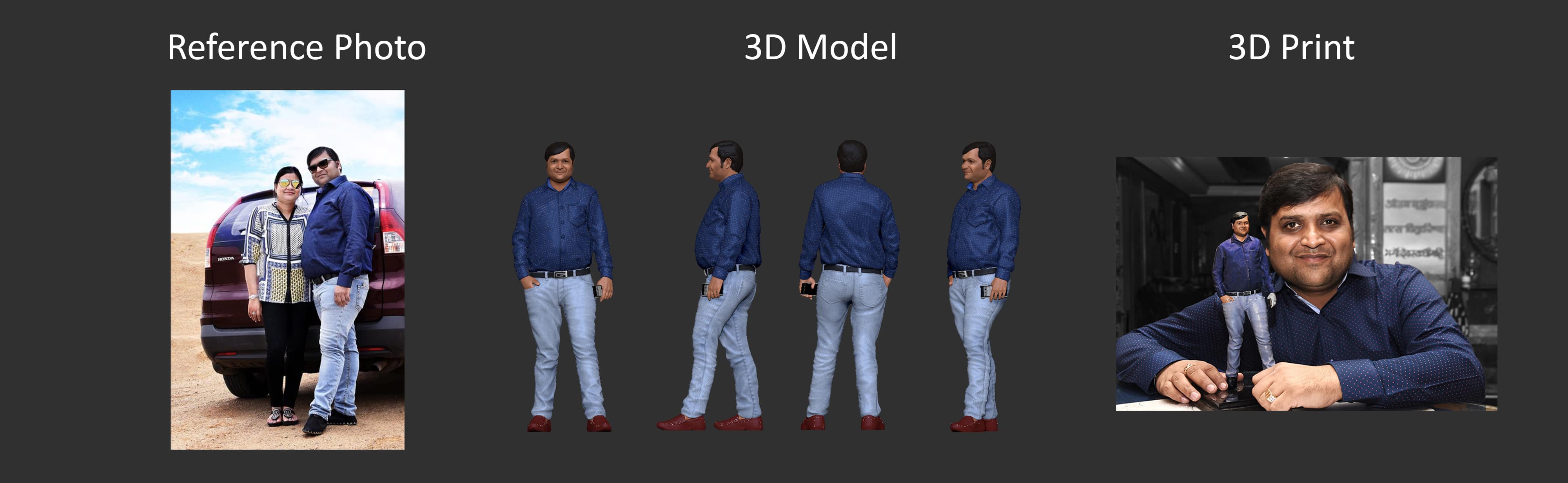

Stage 1 – Creating your digital 3D-model asset

> In stage 1 we will create a digital 3D-representation of your subject/object. This will be an approximation of the actual physical appearance.

> review of reference 2D original photographs (person, animal, object),

> draft model mesh design in zBrush or other digital sculpting tools,

> detailed digital sculpting of target shape/geometry by skilled 3D-artists,

> draft UV map and texture creation

> detailed colour map creation.

Stage 2 – Customer review/ proof of design.

> staging of draft 3D model image to be viewed and assessed in web browser,

> we perform any adjustments on the model as per your requirements,

> One customer feedback and review cycle included.

> For digital-only projects (i.e. no 3D-print): We share a a download link to the finished 3D-model file (output format: obj, mtl, jpg/png)

Stage 3* – Preparation for 3D-colour print production

> Model manufacturability test and mesh adjustments (e.g. wall thickness, cantilever geometry, water tightness, etc.),

> Output file format: obj, jpg, mtl (compressed zip format); compatible with all common 3D-modelling tools.

Stage 4* – 3D-colour print production

> Full-colour 3D-print production in chosen material (Sandstone, aka CJP – Colour Jet Print or Polyjet, aka photo-polymer/resin),

> Production order handling and quality control with our local or overseas third-party print service partner,

> Shipping of finished parts to 3Dfy.me for final quality control and coating (protective, matte UV varnish).

*: stage 3/4 only applicable for projects involving 3D-print production

3D-print material information

Colour Jet Printing (Powder)/ Sandstone

The composite material full-colour prints (CJP – Colour Jet Printing) leave the printer fully coloured, using a fine powdered composite material that resembles sandstone. The print itself is carried out layer by layer and the sandstone material is painted and adhered during the process. We are using modern 3D Systems ProJet Pro printer technology and we print based on the CMYK colour spectrum (390,000 distinct colours) to a resolution of 600×540 dpi. The maximum build size of the parts is 254×381×203 mm and the layer thickness is between 0.089 – 0.102 mm.

Sandstone is a brittle material with a rough surface that must be handled with care. Exposure to water may cause fading, however, our protective, matt coating will provide some resistance to water, moisture and UV-rays. Ideally you keep the figurine away from direct exposure to sunlight (e.g. avoid placing by the window).

This options is the most cost-effective full-colour print solution and great when working under tight project budgets.

Polyjet / Resin (photo-polymer)

Multi-Colour Polyjet is a rigid plastic material printed on the powerful Stratasys J750 3D-printer. The printer uses Polyjet technology by jetting photopolymer materials in ultra-thin layers onto a build tray, layer by layer until the model is completed. Each photopolymer layer is cured by UV light immediately after being jetted, producing fully cured models that can be handled and used immediately. The result is a clear plastic-like look, achieving 500,000 colour combinations (translucent or opaque, vivid full-colour). The maximum build volume is 490 × 390 × 200 mm. Multi-Colour Polyjet is great for durable and highly realistic visual prototypes, medical models, and displays.

Compared to CJP, Polyjet has better mechanical properties, chemical resistance, more vivid colours, smoother surface and offers finer details over all.

MJF Nylon / Full-colour PA12

Using the HP Jet Fusion 580 3D-printer we print thermoplastic in full-colour utilising Multi Jet Fusion (MJF) technology, which deploys two perpendicular carriages to transform powdered plastic (PA12, aka nylon) into solid parts.

Colour permeation is 100% through parts, so if you cut them in half, you see a consistent colour throughout. This is achieved using up to eight chemical agents at a time, with these agents also controlling texture, density and translucency.

The Jet Fusion 580 also has manual voxel control, which enables us to control the physical properties of each voxel – or individual bits of powder – for enhanced control over part strength, appearance, and feature detail. The build volume is a generous 332 x 190 x 248 mm (13.1 x 7.5 x 9.8 inches).

This technology offer the finest details and strength of all currently available 3D-print methods as well as a wall thickness of up too 0,4 mm.

Reviews

There are no reviews yet.